MacroGranometer™ is a computerized sedimentation analyzer of water-insoluble, sand-sized material, using

gravity sedimentation from a single level (stratified

sedimentation) in water. Employing the most sophisticated solutions

makes it the unique tool for sand sedimentology,

which provides high quality and meaningful results, with added operational and maintenance ease, and

a variety of outputs.

MacroGranometer™ measures the

sedimentation velocity distribution,

and its data processing program, SedVar™, converts it into a distribution of

other sedimentation

variables, such as shape-specified grain size. For the conversion, the equation for drag coefficient as a function

of Reynolds' number and grain shape developed by J.

Brezina (1979b) is utilized.

Distributions of the

following sedimentation variables are

available:

- sedimentation velocity, in three versions:

- laboratory

- standard

- local

- shape-specified grain size

- grain shape

- grain density

- Reynolds' number

The grain parameters density and

shape

can each be quantified as a distribution. This is possible

from samples of nearly equal grain size such as narrow sieve

fractions.

Our processing software SedVar™ also computes distributions of the grain

sedimentational Reynolds' number; these distributions, similarly

to those of PSI sedimentation velocity, feature a less negative skewness than

the pertinent PHI grain size distributions. In fact, the skewness of the grain

sedimentational Reynolds' number distributions has a medium value between the

most negatively skewed PHI, and least negatively skewed PSI distributions).

Not only that our Reynolds' number distributions use the shape-specified grain

size but can be computed for samples of nearly equal grain size (narrow sieve

fractions with varying grain density), and for nearly equal grain density.

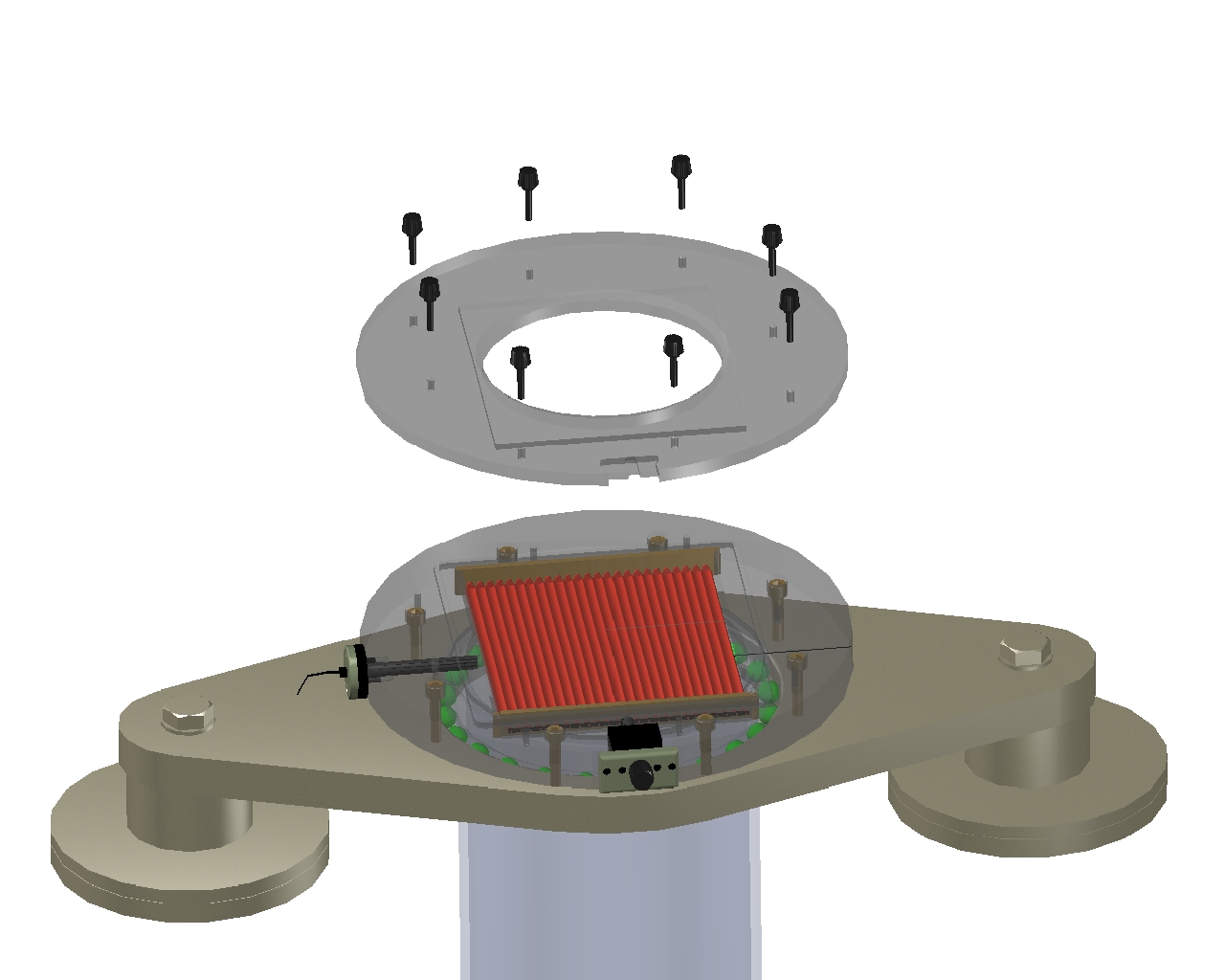

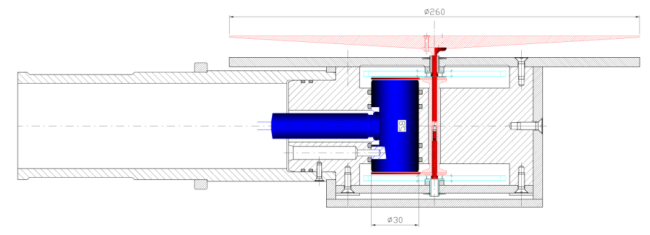

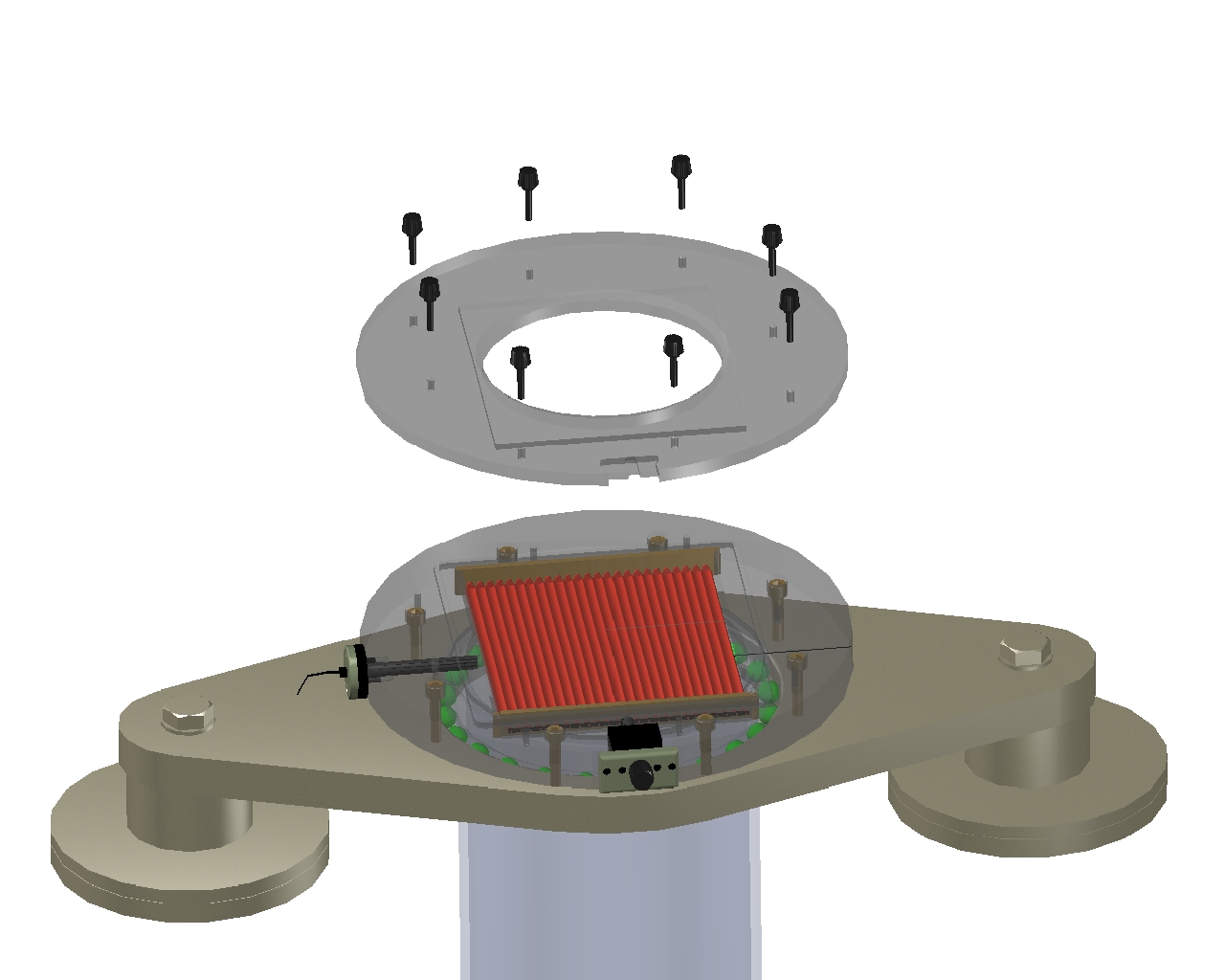

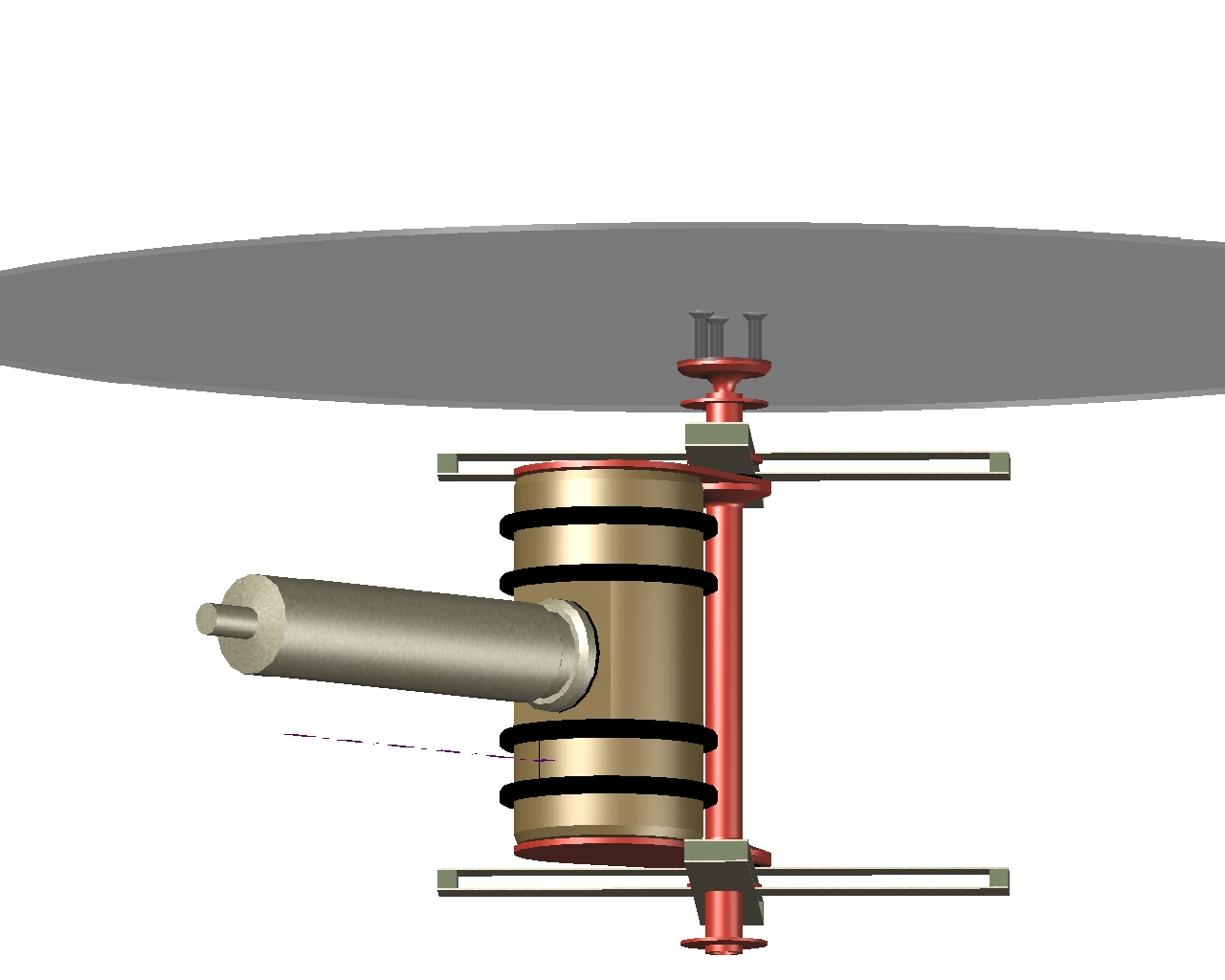

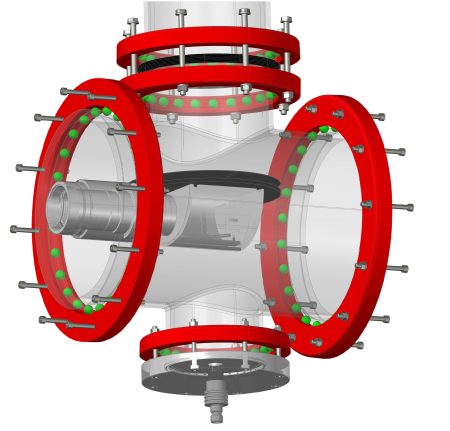

The MacroGranometer™ system is shown on the

schematic view below:

|

|

3a

GRM™, Measuring & Operational Software

example of the GRM™ analysis window

(User's 486 66

MHz DX2 PC or higher, with 1 LPT and 1 COM interfaces)

2

Control & Measuring Electronic Box

CFM automatic digital amplifier, control

& sensor PCBs,

power supply, cable distributor

3b

SedVar™, Processing Software

|

|

The schematic view of the

MacroGranometer™

the sedimentation length L is usually 180 cm |

|

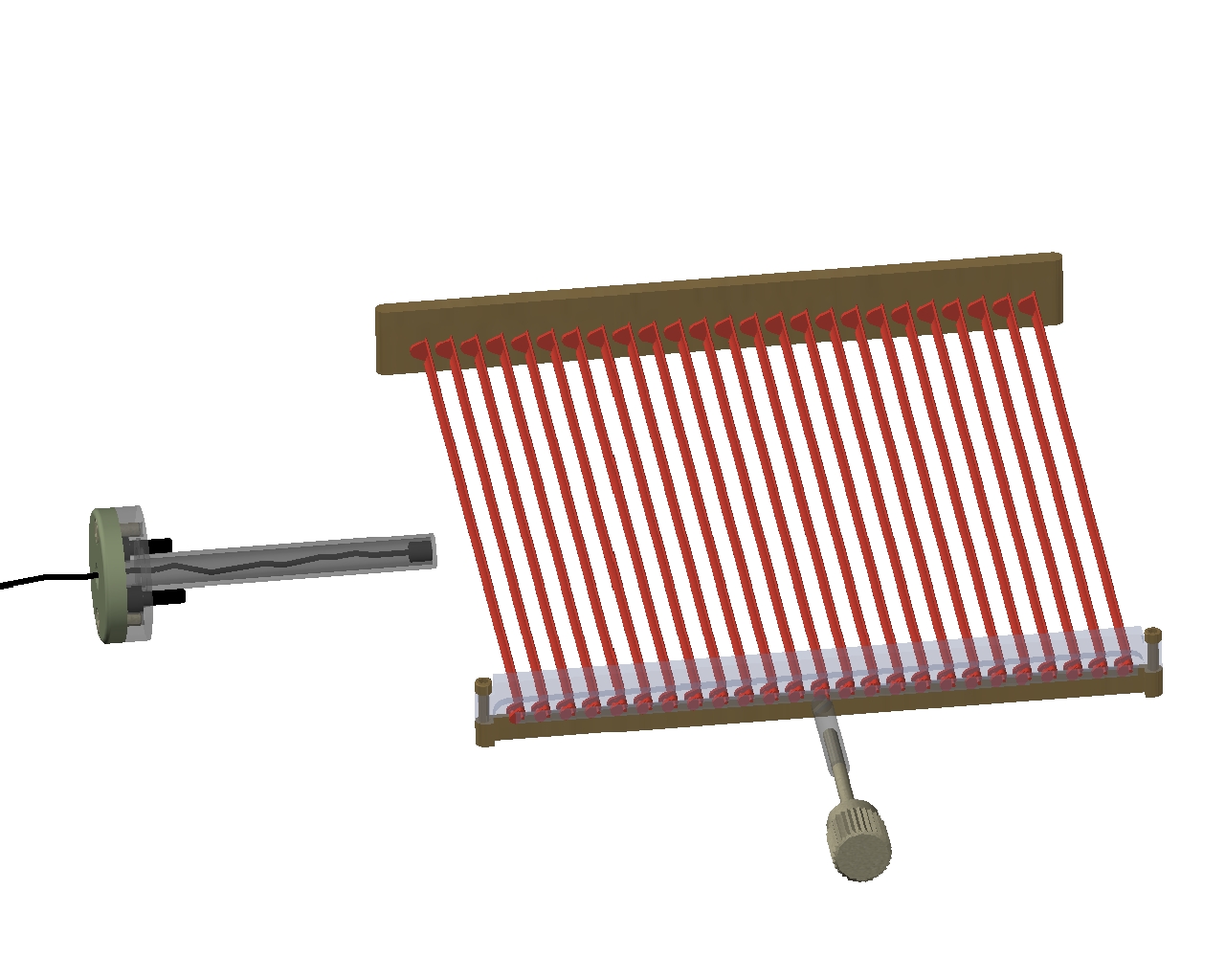

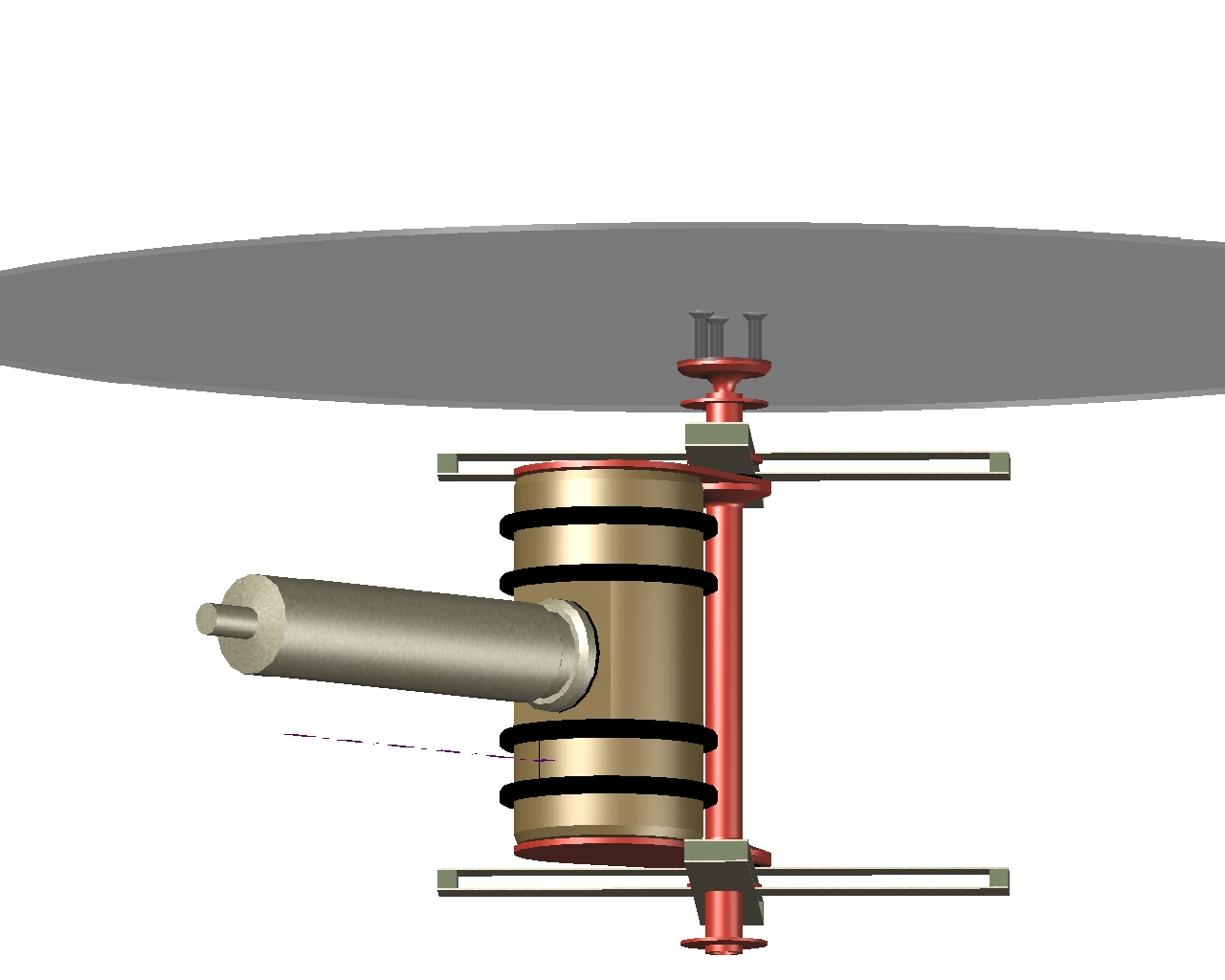

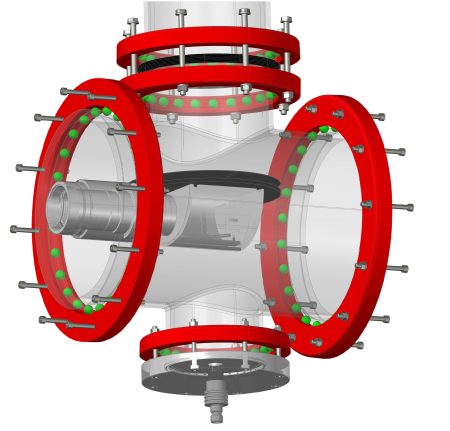

3-D view

of the

Upper Part of the Sedimentation Tube: Venetian Blind (sample introduction)

3-D view of the MacroGranometer's™

Sedimentation Tube

(larger view: klick) |

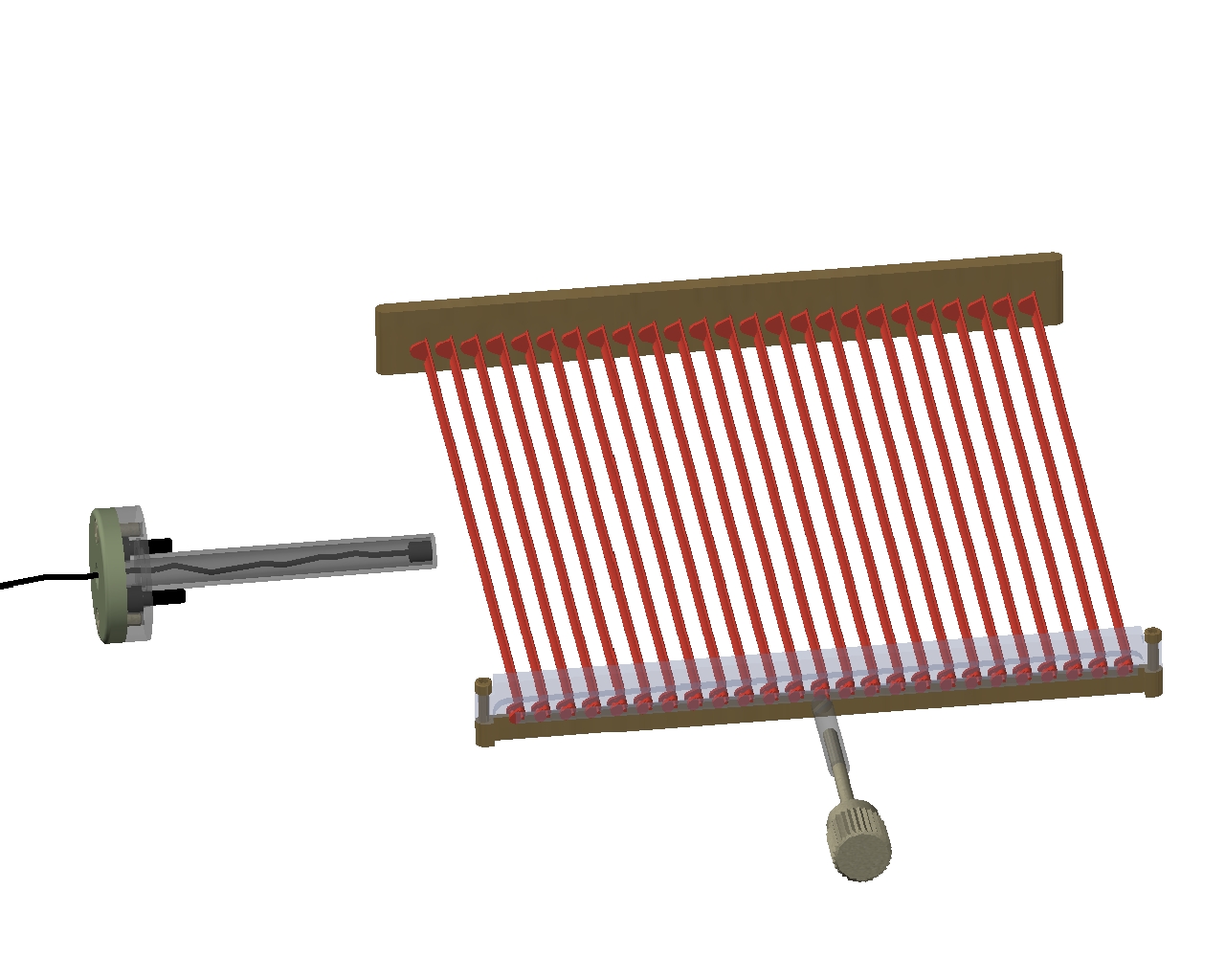

Open

lamellae of the Venetian Blind

(without rotational magnet etc.)

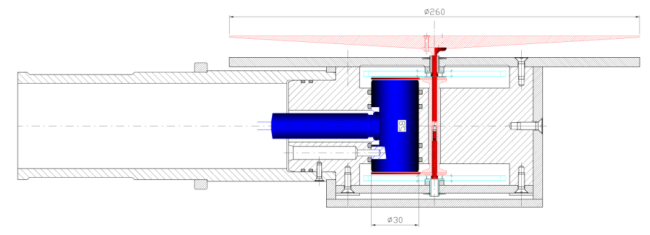

Underwater Balance Body

(larger view: klick) |

3D-View of the Underwater Balance Body

3-D view

of the

Lower Part of the Sedimentation Tube with the

Underwater Balance

(larger view: klick) |

|

Our measuring software

GRM™ runs on the user's 486 DX2 66 MHz PC or higher, under MS DOS 6.2 or higher. It controls the system's operation and stores the

measured data as ASCII files.

Our processing software

SedVar™ runs on the user's MS Windows

98 PC or higher. It processes the measured PSI local sedimentation velocity

distributions.

SedVar™ consists of three parts:

- SedVar™, distribution conversion,

- SedGraph™,

graphical output

generator,

- Sed 3D Graph™,

3D plot of a multiple distribution graph.

|

|

MEASURING RANGE: |

0.016 - 4 mm |

|

quartz

density materials: |

0.044 - 4 mm |

|

heavier materials: |

may be finer, such as 0.016

- 1 mm; |

|

SAMPLE SIZE: |

smallest, statistically representative

samples of

15,000 - 20,000 grains (0.1 - 5 gram); |

|

settling rate resolution: |

0.02 PSI |

|

weight resolution: |

0.01 % |

RESULTS: semi graphic and full graphic print-outs showing distributions

of the six sedimentation variables listed above, such as laboratory, standard and local

PSI sedimentation velocities, PHI grain

size, density, shape factor and Reynolds' number including either variable size, density

or shape factor. The standard sedimentation velocity and Reynolds' number are available also for

sieve fractions (constant size) and heavy liquid fractions

(constant size and density);

each variable is resolved into 401 logarithmically equidistant intervals.

Mean, spread,

asymmetry & peakedness are calculated as

moment and percentile distribution

characteristics of each variable. Other characteristics may be included as

you wish.

The program

Sed 3D Graph™ (part of the SedVar™ program) permits a graphical display of a

group of

distributions, either according to the samples' geographic

horizontal or vertical location, or according to another desired variable. For

example, a group of PSI-settling velocity (or grain density) distributions, each

from a constant grain size fraction, can be plotted according to their PHI-grain

size.

The optional program

SHAPE™ provides the possibility of

separating as many as five mixed distribution components, each normally

distributed. This program can match a sieve analysis to the sedimentation analysis of the same sample, and compute Shape Factor values

to each

0.02-PSI sedimentation velocity. Our SedVar™ program can use this set of the

variable

SF values to adjust the sedimentation grain

size distributions of similar samples (the results of the MacroGranometer™) to the

sieving; in

other words, it can simulate the sieving errors.

Examples

of our clients

who use the instrument

-

Department of Geological Sciences,

University of Trieste, Italy (click);

-

Department of Geology, University

of Vienna, Austria (click).

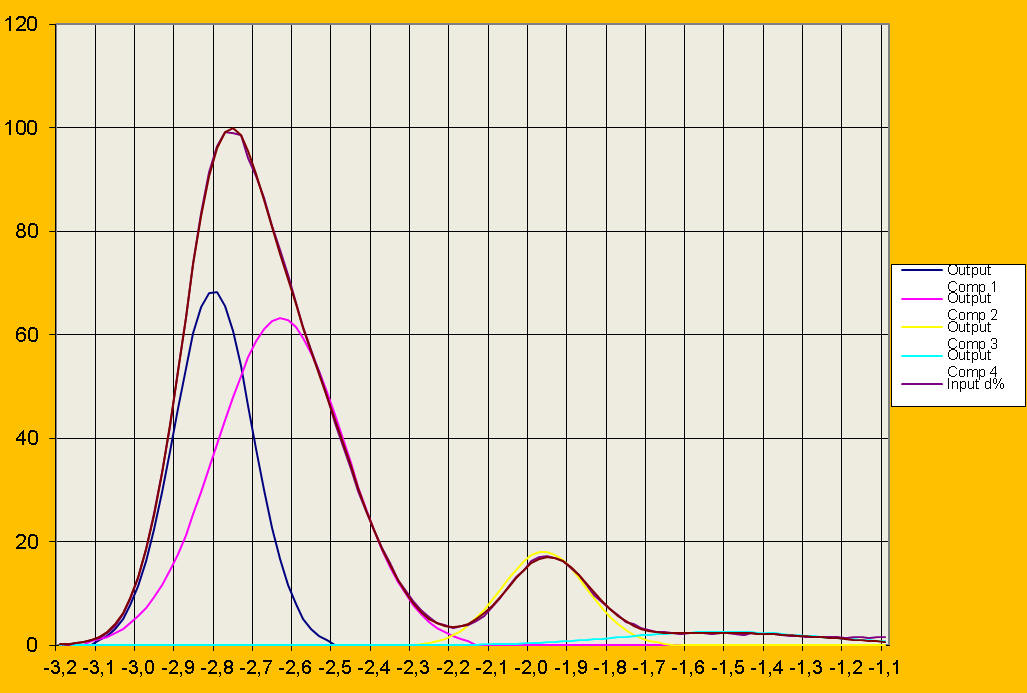

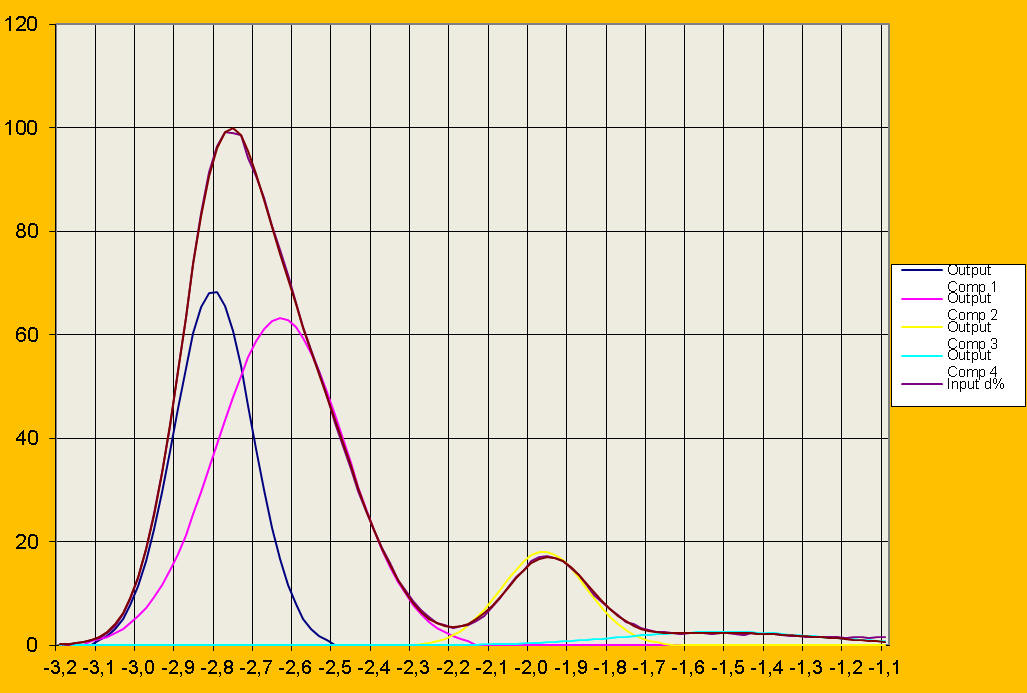

Example of a PSI distribution decomposed into Gaussian components

SAMPLE:

FileName:

sed122.dat

A sand

fraction, consisting of nearly monosize grains, made by precision sieves with

circular holes:

|

Material:

|

black sand

|

sample 13

|

at a 90° intersection of beaches

|

|

Locality:

|

near Casusay

|

Venezuela Bay

|

about 110 km NNW of Maracaibo

|

|

Sampling Date:

|

1972-5-15

|

low tide

|

tide amplitude: about 75 cm

|

|

Analysis date, time:

|

1981-2-1, 16:55h

|

Tmean

= 24.76°C

|

|

Preparation:

|

precision wet vibration sieving

|

circular holes ± 0,002 mm

|

|

MonoSize:

|

1.770 ±0.0639 PHI

|

= 0.297 ±0.013 mm

|

|

Average of 8 sample

split analyses:

|

Total Mass:

Mean Sample

Split Mass:

|

0.6916 gram

0.08645 gram

|

SF = 0.63 (calculated Corey‘s Shape Factor)

Glab = 980.962 gal (cm/sec2)

|

PSI Distribution

of

MonoSize

(1.77PHI=0.297mm)

Polymineral

Fraction

Decomposed into

4 Gaussian Components

Our Sand Sedimentation Analyzer™

(MacroGranometer™)

measured at 0.02 PSI intervals (X-axis).

No data manipulation such as “smoothing“ has been used.

The smoothness

of the 1st derivative,“Input d%“, shows the

analysis quality.

Our Program SHAPE™

identified

4 Gaussian Components (Comp

1,

Comp 2,

Comp 3

and Comp 4).

Our

Program SHAPE™

(based on the method by Isobel CLARK,

1977)

decomposed

the analyzed

PSI

distribution into

4

Gaussian

components

with the following 11

parameters

-

4 means, 4 standard deviations, 3 percentages

(the 4th one is the rest up to 100%):

|

#

|

PSI-mean

|

St. Dev.

|

%

|

Density

|

Minerals

(calculated & confirmed)

|

|

1

|

-2.8095

|

.1007

|

34.56

|

4.76

|

ilmenite

|

|

2

|

-2.6376

|

.1645

|

52.15

|

4.16

|

garnets

|

|

3

|

-1.9685

|

.1090

|

9.90

|

2.65

|

quartz,

feldspars, calcite

|

|

4

|

-1.5137

|

.2601

|

3.39

|

2.08

|

porous

calcite (fossils)

|

|

Goodness of fit

|

Chi-Square:

|

χ2 <0.01

|

Our Program

NGRM™

calculated density from the constant PHI size and each PSI-mean value.

The density

values of each component match the minerals identified microscopically and by

X-ray diffraction analysis.

Our Program SedVar™ converted the variable PSI into

a log

density distribution (not shown here).

The ultimately

lowest Chi-square value, χ2 <0.01,

reveals the

decomposition quality.

Client's preparation

for our installation of the

instrument

The client should build and fix

two steel Bases to carry both the Air Shock

Absorbers, and an operation

platform before our installation. Also, a container with about

100 liter distilled water should be available a few days before our installation

(the container should be positioned above the top of the sedimentation column in

order its water will be warmer, and without dissolved air).

J. Brezina collected and processed the data of the Experiment from 17

participants, however, he did not complete the final processing before the

publication deadline of the book by J. P. M. Syvitski

(click on the author's review of the Syvitski's book

in Basin

Research 4/1992).

Below are shown the calibration results of one of the

MacroGranometer™ users, the participant No. 14 (in the Syvitski's book quoted

under instrument code ST3), in comparison with a precision 0.25-PHI

sieving, made by participant No. 7.

The calibration samples consisted of glass spheres with exactly determined density of each of the five

mixture components; three sand samples were mixtures of up to three components. J. Brezina produced

each mixture component on 65-millimeter screens featuring galvanically deposited

meshes with circular holes, with the aid of random vibration of the glass

spheres in alcohol suspension on each screen. The minimum material on each

screen enabled that only one-layer of spheres has been screened until constant

amount of retained spheres (zero throuput), which resulted into ample sieving time.

The component portions have been

obtained on a high precision rotational sample splitter using the slowest

possible samples' flow. The high statistical representativity of each split was

confirmed by the negligible variation of the weight of each component split.

Still, each sample had a specific percentage of the three components, and, this

way, has been produced exclusively

for each participant.

The percentages of each three sieve fractions of the

Sand 1 are shown in the Table below, column headed by "14" for the

Participant 14 (Syvitski's code "ST3"), who analyzed the sub-sample [split]

4, = "14S1S4") by the MacroGranometer. This sub-sample had a mean density

2.487125 g/cm3.

For comparison, three sieve fraction percentages of

the Sand 1 are shown in the same Table, column headed by "7" for the Participant

7, who analyzed the sub-sample 2 by a carefully executed sieving at 0.25

PHI.

| Participant-# |

14 |

7 |

| # |

PHI-mean |

mm |

g/cm3 |

% |

% |

| 1 |

0.515±0.010 |

0.700±0.005 |

2.5050 |

25.3 |

26.0 |

| 2 |

1.000±0.015 |

0.500±0.005 |

2.5035 |

20.7 |

20.6 |

| 3 |

1.498±0.020 |

0.354±0.005 |

2.4700 |

54.0 |

53.4 |

The MacroGranometer™ analysis by the participant 14 of the same sample, and

decomposed by our program

Shape™ have recovered the original three distribution components very closely:

| # |

PHI-mean |

mm-mean |

PHI-standard deviation |

% |

| 1 |

0.5840

|

0.667 |

0.0698 |

22.39 |

| 2 |

0.8733 |

0.546 |

0.0842 |

26.99 |

| 3 |

1.4926 |

0.355 |

0.1053 |

50.63 |

Below are the graphical plots of the MacroGranometer™ analysis (participant

14, sand 1, sub-sample 4 = 14S1S4.dat):

Example of an analysis processed by SedVar

™

into

frequency and cumulative curves

(the frequencies are plot in linear scales).

The sample 14S1S4 was a calibration material consisting of glass

spheres, participant 14 ("ST3"), sand 1, sub-sample (split) 4.

Example of an analysis processed by SedVar

™

into cumulative curve

(the cumulative frequency is in probability scale).

The same sample as above.

Below is the graphical output of our SHAPE™ program (produced by MS EXCEL

program):

Below is the result of standard sieving (at 0.25 PHI intervals) by the participant 7.

The

histogram above suffers from three fundamental shortcomings of the sieving

(at 0.25 PHI) in comparison with a sedimentation method

(at 0.02 PHI):

- The sieving, using 12.5-times wider intervals than the

MacroGranometer™, resolves only two instead of three components. The third component

can only be suspected

according to the asymmetry of the smaller distribution component.

- The sieving is shifting the results by its interval width

(0.25 PHI = 1/8 of the grain size) toward finer grain size.

- Nonspherical particle shape affects the sieving size inconsistently with specific surface: particles with

nonspherical shape are sieved as coarser, whereas their specific surface is

greater as that of the finer particles.

Please note that Syvitski has not:

-

exactly

known the size distributions of the test samples synthesized by J. Brezina, therefore his evaluations

could not be appropriate;

-

identified the mixed distribution

components by a program such as our Shape™.

Five types of settling tubes provided clearly better results

than all other tested instruments (image analyzer, Coulter-Counter™,

Malvern™ laser particle sizer, SediGraph™, photosedimentometer Lumosed™).

From the five settling tubes,

three ones (two of them were MacroGranometers™) qualified as Advanced

Settling Tubes. The output of both MacroGranometers™ best matched the

expected results using the above shown highly demanding criteria (fit of the

mixed distribution components).

The

other

settling tubes, and particularly other instruments, could even not reproduce the

original fractions. The component modes were so strongly shifted that they could

hardly be recognized as formed by the original fractions; frequently, additional

modes formed or some of the modes disappeared.

Top page.

Return to Home.

You are visitor number  since July 17, 2000

since July 17, 2000